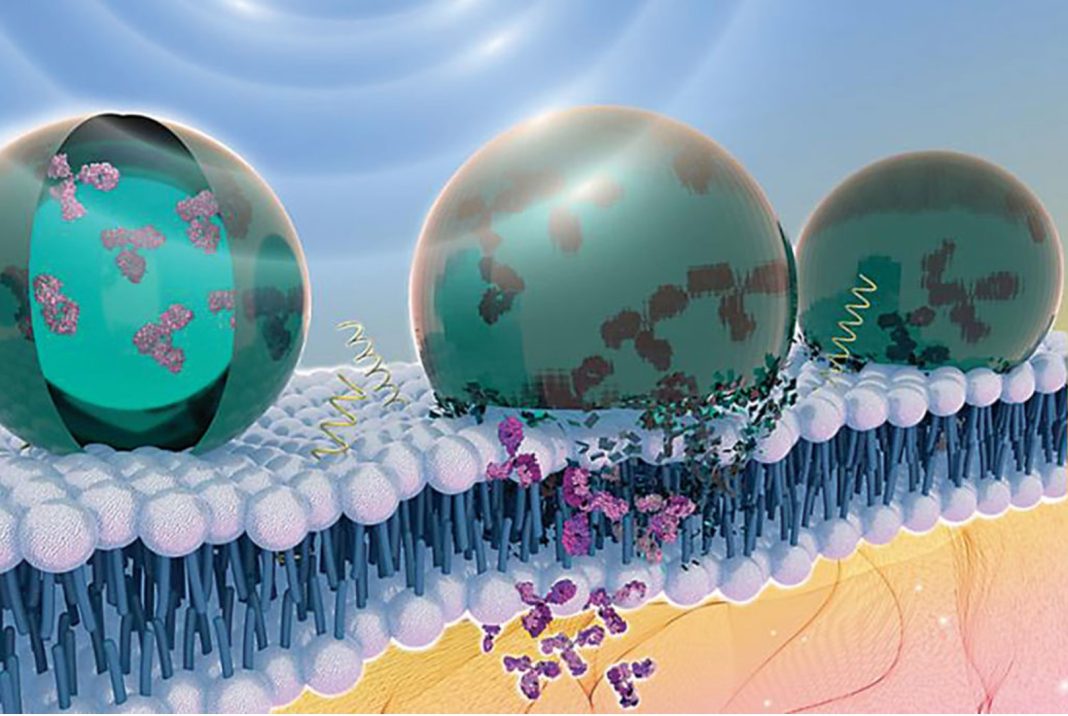

Nanomaterials are being engineered to facilitate a range of applications in diagnosing diseases and delivering drugs. The widespread adoption of nanotechnological applications in medicine rests on the ability to safely target nanomaterials and understand how they behave in biological tissue environs once they have completed their intended tasks.

A study published in Nature Protocols titled “An analytical workflow for dynamic characterization and quantification of metal bearing nanomaterials in biological matrices” has developed a comprehensive workflow that enables the detection, characterization and quantification of metal-containing engineered nanomaterials in biological systems at trace-level concentrations. The workflow enhances the safety and targetability of nanotechnology applications in medicine.

“This is the first comprehensive protocol for analyzing what happens to nanoparticles in humans and organisms after use. This is an important step in understanding how nanomaterials behave, hopefully allowing nanotechnology to reach its full potential one day,” said Fazel Monikh, PhD, a researcher at the University of Eastern Finland who is the lead author of the study.

Unlike earlier methods that have attempted to detect and quantify metal-bearing nanomaterials in biological systems using fluorescent dyes or radiolabels, the workflow presented in the new study uses a range of analytical techniques such as, single-cell inductively coupled plasma mass spectrometry (scICP-MS), single-particle inductively coupled plasma mass spectrometry (spICP-MS) and synchrotron X-ray absorption fine structure spectroscopy (XAFS), that are not dependent on dyes, radiolabels or fluorophores.

The method can be used to analyze the fate and behavior of engineered nanomaterials in a range of biological samples, including in a single cell, a cell layer, tissue, organ, whole organism or physiological media. Researchers can use the method to analyze media samples such as blood, gut contents, or hemolymph, and different organisms including bacteria, animals or plants.

Protocol overview

The protocol contains three sequential modular procedures: first, the in situ measurement of the engineered metal-bearing nanomaterials in individual cells; second, the measurement of the nanomaterials upon extracting the particles from their biological origin; and third, the in situ characterization of changes in the nanomaterial while in the biological systems (biotransformation).

The first procedure consists of sample preparation for in vitro cellular experiments or single microorganism analysis, followed by quantification of cellular association using scICP-MS. scICP-MS requires a small number of single cells, roughly 3,000 cells per milliliter, depending on the size of the individual cells. Unlike cytophotometry, scICP does not require staining cells or labeling nanoparticles and can quantify the amount of nanomaterial in cells or at the surface cells in a population.

The second module of the workflow involves dissecting tissues out of the organism, isolating particles from biological samples, stabilizing the extracted particles to prevent them from sticking together (agglomeration), separating the particles by size if needed, and quantifying them using analytical techniques such as ICP-MS, spICP-MS, TEM (transmission electron microscopy), DLS (dynamic light scattering) and NTA (nanoparticle tracking analysis). These analytical techniques measure the distribution of particles, their size, shape, and release of ions.

The third and final module includes four options where the biotransformation of the metal-bearing engineered nanomaterials in organisms is characterized using XAFS, plant samples are quantified using μ-XRF (micro-X-ray fluorescence) or STXM (soft transmission X-ray microscopy) or cell lines are analyzed using STXM.