Within biopharmaceutical companies, crystallography is generally the purview of research scientists involved in structure-based drug design. Its potential for protein purification has been known for the past century. Today, crystallography finally is emerging as an approach to purify monoclonal antibodies (mAbs) and other proteins in continuous biomanufacturing processes.

In what appears to be a first, scientists from The Pennsylvania State University used crystallization and TFF to filter human serum albumin (HSA), according to a recent paper. In contrast, centrifugation, which typically is used for washing and removing liquid from crystalized solids, can’t easily be applied to continuous bioprocessing.

“This continuous crystallization-hollow fiber tangential flow filtration (TFF) process could provide the basis for a novel low-cost method for producing mAbs for treating cancers, as well as new therapeutic targets like Alzheimer’s,” principal investigator Andrew L. Zydney, PhD, professor of chemical engineering, Penn State, tells GEN.

PEG helps

The scientists began by crystallizing human serum albumin (HSA) by adding trivalent cerous chloride (CeCl3), both with and without polyethylene glycol (PEG).

“The addition of PEG (from 0 to 12 percent) had minimal effect on the crystallization yield, but it did lead to the formation of larger (and more spherical) and denser crystals,” Zydney reports. That “significantly improved the filterability of the crystals by changing the particle morphology and size distribution.” The addition of PEG also appears to reduce the potential for fouling. In the presence of three percent PEG, HSA crystallization occurred within 20 seconds, and the protein yield exceeded 85 percent.

During the 24 hours the experiment ran, transmembrane pressure remained below 5 kPa (less than 1 psi), which suggests continuous crystallization followed by TFF may be a practical approach to purify high-value proteins for continuous biomanufacturing. “Without PEG, the transmembrane pressure exceeded 10k Pa within five minutes,” they noted.

Previous studies have shown crystallization and washing have potential as a purification method for monoclonal antibodies and other recombinant proteins. Crystallization can produce proteins that are nearly pure in only one processing step. It is scalable and stable, but, hasn’t been used to continuously manufacture proteins.

Nonetheless, researchers have been working to develop improved methods that are both effective and cost-conscious. One, for example, used a carousel of normal flow filtration units that operated continuously.

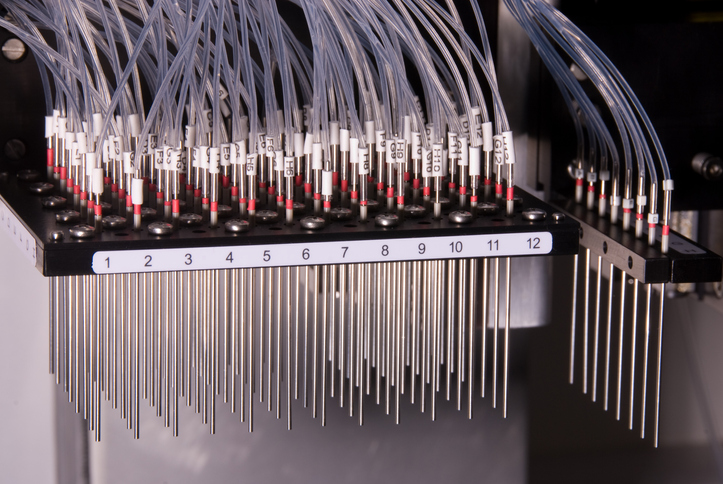

Compared to other emerging methods, TFF, Zydney suggests, is “a potentially more attractive approach for the continuous processing of protein crystals.” The technology is well-known in the industry and recent studies show it can be used to dewater and wash precipitated proteins, “including HSA and mAbs.”

“The key is to operate the TFF device below the critical flux,” Zydney stresses. “We are exploring new methods to optimize the purification process by controlling the morphology and size of the protein crystals as part of a contract with the FDA that involves an ongoing collaboration with colleagues at MIT and RPI.”