Bioprocessing appears always to need more analysis and modeling. As Alexis J. Torres, PhD, of Pfizer’s manufacturing science and technology group in Sanford, NC, reported in the Biotechnology Journal, “The biopharmaceutical industry is slowly making progress with the implementation of manufacturing intelligence principles including process analytical technologies (PATs) and modeling, however, the implementation of such technologies still lag in comparison to the chemical processing industry.”

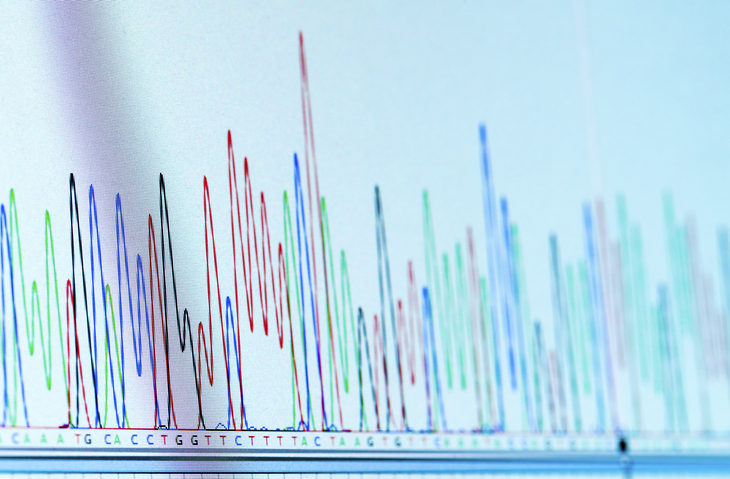

Part of bioprocessing’s lag comes from “the red tape involved in implementing new technology in manufacturing,” Torres noted. In addition, bioprocessing produces complex data. “Process information can be daunting to analyze as it consists of initial conditions, discrete and continuous process data, as well as numerous orthogonal analytical test results,” Torres wrote. In particular, Torres looked at chromatographic separations, and how analysis can track the performance of columns and even compare that performance as a process is scaled up.

Strong anion exchange column

Using a strong anion exchange column, a Pfizer team purified a gene therapy product based on an adeno-associated virus (AAV). Then, they used principal component analysis (PCA) to compare chromatograms between batches. With multiple linear regression analysis, the scientists looked for variables that impact the area under the peaks in chromatograms, which quantify the removal of impurities, such as host-cell DNA, from the product.

For such impurities, Torres pointed out, “analytical data was leveraged to create a model that would be able to predict the results from the analytical lab testing based on information gathered from the chromatograms.” Consequently, this model could be used to reduce some testing in manufacturing a product.

These models can also be used in developing a bioprocess. “The chromatograms from small-scale runs can be compared to commercial scale runs and a PCA can be performed to the normalized chromatograms,” Torres explained. “This approach would allow for a more systematic analysis and comparison of chromatograms across scales that would remove the subjectiveness of visual comparison.”