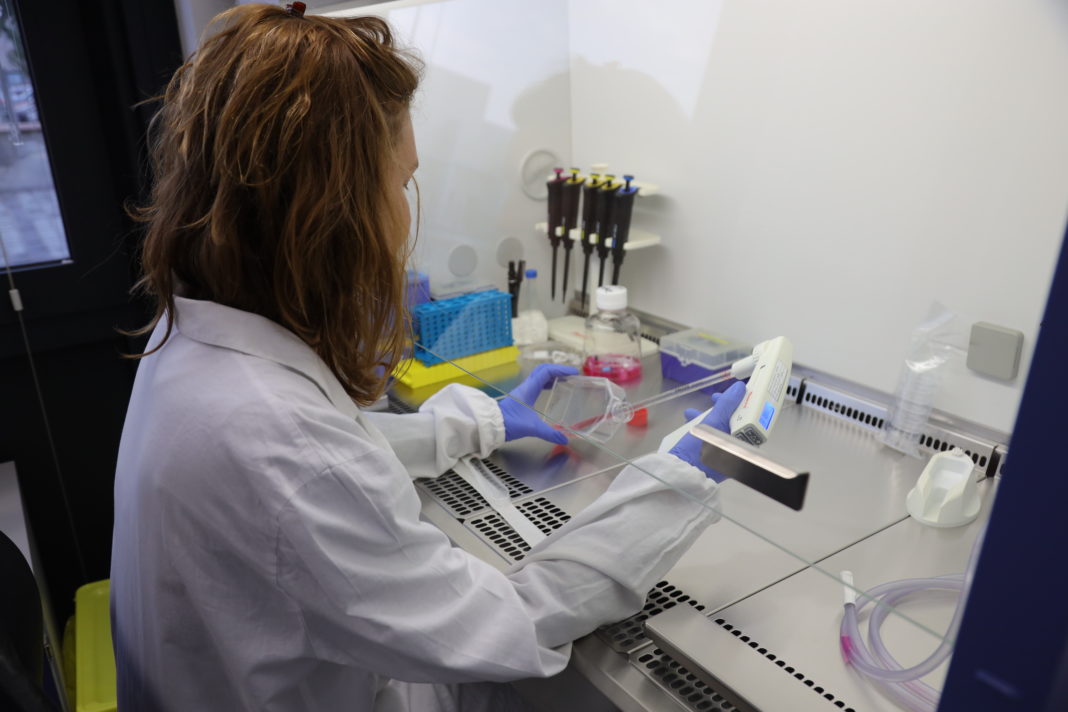

Cell therapies might be manufactured closer to patients to reduce shipping challenges. [Rigenerand]

Several elements of making cell therapies create significant obstacles in getting these treatments to more patients.

“A main challenge for cell therapies—autologous or allogeneic—is cryopreservation in the supply chain,” says Simona Guidi, business development director at Rigenerand. “Products have a very short shelf life, sometimes hours or days.”

That obstacle prevents many patients from getting such treatments. A potential solution involves getting the production closer to patients. “That is a big issue,” points out Guidi.

One way to accomplish that “is to move to an allogeneic setting,” says Massimo Dominici, MD, scientific founder of Rigenerand, “but it is challenging to move from autologous sources.” Even Rigenerand’s first product will be autologous.

Alternatively, Dominici thinks that the storage method could be improved. “In the cryo-biology related to manufacturing, we use the same reagents that were used 30 years ago,” he says. “No one knows what’s going on after freezing.”

Through novel technologies and reagents, the cell-therapy industry will explore storing the cells at –80° Celsius or even –20°. “Maybe we can find ways to freeze products that allow for better performance,” he continues.

Maybe the best method of all to expand the use of cell therapies involves bringing the manufacturing closer to the patient. To do that, Guidi says, “we are developing a 3D bioreactor to be used in a really easy way that is suitable for manufacturing of cell therapies for clinical purposes.”

These ideas—all under development at Rigenerand—will take time to get them to the market.

“Cell therapy is moving its teenage time to a mature state,” according to Dominici. “It will take time to complete that maturation.”

But it’s worth it to improve the cell-therapy supply chain.