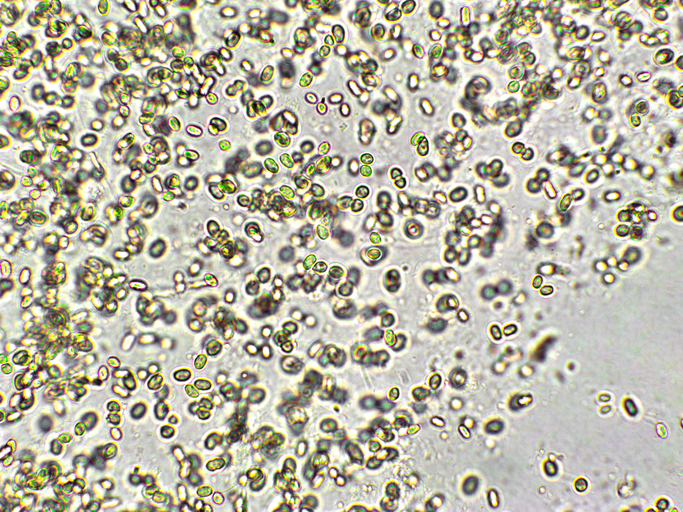

Because microalgae grow in light and lose biomass in the dark, traditional fed-batch bioreactor strategies are sub-optimal, limiting algae’s value to biopharmaceutical manufacturers. Now researchers at Johns Hopkins University (JHU) have developed a genome-scale metabolic model for Chlorella vulgaris to optimize nutrient use during those cycles.

It allowed researchers to reduce glucose requirements by 75 percent and nitrate requirements by 23 percent, while maintaining biomass densities that were at least 80 percent of those of a glucose-fed heterotrophic culture. Light-dark cycling accounted for three-fold yield increases (per gram of glucose) for biomass, lutein, and fatty acids.

A closed-loop glucose and nitrate feed system “optimized for dark cycles and that accounts for shading during light cycles increased biomass yield 122 percent more than normal fed-batch cultures,” according to a recent paper. This makes algae an increasingly competitive and sustainable biomanufacturing option.

Cells’ metabolism varies during the cell expansion phase and the production phase, Chien-Ting Li, PhD, first author, and, at the time, a member of the Michael Betenbaugh lab at JHU, tells GEN.

“Traditionally, biomanufacturers used tools such as design of experiment (DOE) to see how different process parameters affect critical quality attributes and used proportional-integral-derivative (PID) controllers to regulate those parameters in the process. This model-driven approach can be a good strategy to control nutrient supplies by considering cells’ metabolism (during their expansion and production) phases… and under light and dark periods.”

Adopting this strategy

To adopt this strategy, biomanufacturers must adapt their current controller system, locate genome-scale models for their cell lines, and ensure this approach meets regulatory guidelines.

“Most commercially-available controller systems do not provide users access to implement their own models,” Li says. “Therefore, biomanufacturers need to build the interface between the software and the controllers. The process measurements—either on-line or in-line—can be transferred to the models, and the model can send the decisions to the controllers.”

Genome-scale models have existed for the past 20 years, but if the needed models are not available, biomanufacturers would need to build their own models.

Li also advises biomanufacturers to develop a validation protocol for this approach. Additionally, he says, “Biomanufacturers need to consider implementing process analyzers to generate real-time data to ensure quality assurance and to support regulatory decisions in this model-based approach.”

This research focused on optimizing nutrient supplies to achieve high productivity. Before it can be implemented commercially, however, Li says product quality also must be considered. “This can be the glycosylation pattern for monoclonal antibodies or the full/empty ratio for gene therapy. Those factors can be strongly influenced by cell metabolism,” he points out. Additionally, this research was conducted using 2 L bioreactors. Results may vary with differently-sized bioreactors.