Bioprocessing 4.0 is now accepted by the biotechnology community as a responsive, self-correcting, complex system, and a radical break with the past. It should not be thought of as a laundry list of incremental improvements, but rather as a completely different approach to engineering and purification of biologic drugs. Its most important feature is self-optimization, built on a fundamentally new theoretical structure.

But there are other technologies in current medical science that are also undergoing significant change. Stem cells are a critical component of modern medicine; could their development be described as stem cell 4.0?

“We are constantly upgrading our tool set,” says Chris Mayhew, PhD, director of the Stem Cell Facility at Cincinnati Children’s Hospital, “Evaluating new growth factor cocktails, and designing new and improved viral vectors. However, our fundamental goals have not changed over the years.”

“We isolate pluripotent stem cells from patients to aid in diagnosis and treatment of a variety of disorders. Our long-term mission is to advance our understanding of a wide range of genetic maladies.”

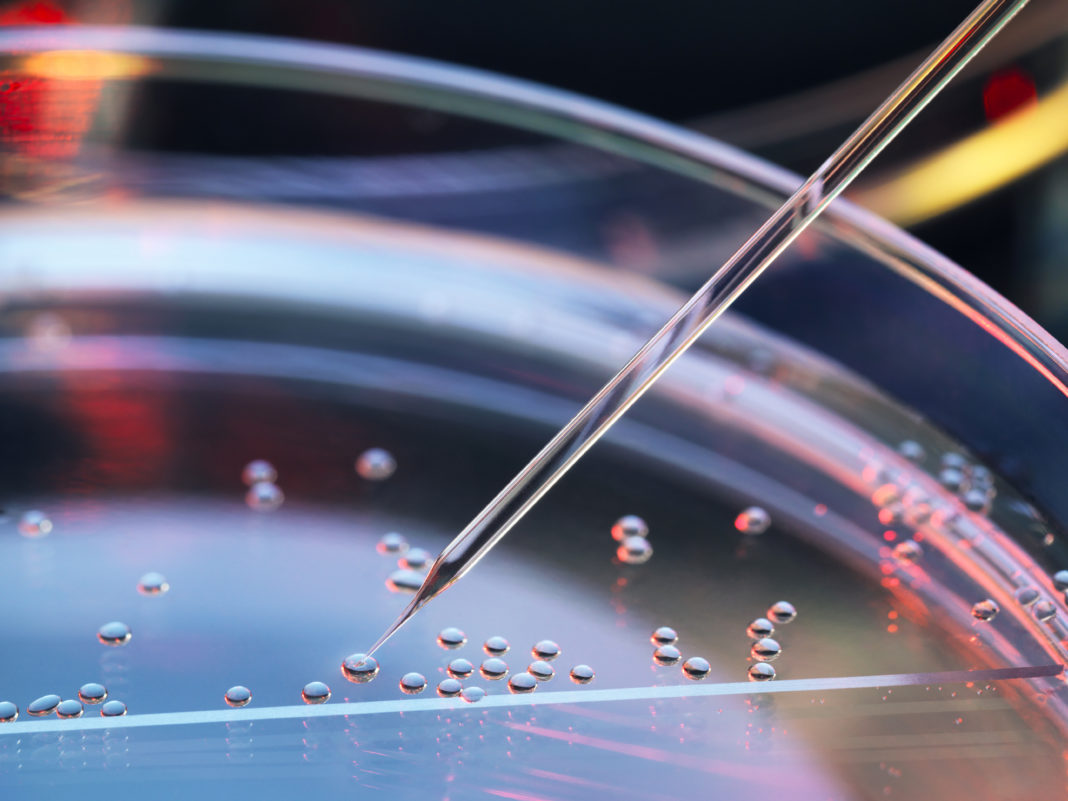

The process involves beginning with the acquisition of blood samples from patients, and subjecting these cells to conditions that select for pluripotent stem cells. Cells are plated and individual colonies selected and isolated by hand. Promising candidates can be programmed through manipulation of culture conditions to differentiate into liver, cardiac or other differentiated cell types that are then characterized and evaluated for their response to a range of therapeutic agents.

Labor intensive and time consuming

“The process is extremely labor intensive and time consuming,” he continued. “It requires several months from the initial steps to completion, yielding a differentiated cell line from each patient that can be toxicity tested for sensitivity to therapeutic agents under a wide variety of conditions.”

There are automated systems for stem cell isolation and processing, but these are not cost effective for an individualized protocol aimed at benefiting individual patients with life-threatening conditions such as muscular dystrophy, cardiovascular disorders, and autoimmune dysfunction.

“At present the manual technology that we apply is not easily scalable,” Mayhew said. “In the last decade we have carried out over 500 projects, each one of which takes around four months to complete. We now have a collection of hundreds of cell lines.”

But Mayhew’s dream project would be to develop stem cell lines from every patient with a particular disease, and compare their stem cells’ response to different programs and treatments.

“Imagine if we could produce stem cells from every patient that was diagnosed with cystic fibrosis,” he suggested. This disorder is one of the most frequent conditions observed in individuals of Caucasian ancestry. It is characterized by the production of thick, viscous mucous that damages the lungs, leading to often fatal complications.

While there are a variety of treatments that can prolong the life of the patient, this disorder is currently incurable. “CF patients present with a variety of clinical manifestations, and sometimes we observe striking differences in individuals with the same mutation, phenylalanine 506 in the cystic fibrosis transmembrane conductance regulator (CFTR) gene,” explained Mayhew. “And there are a variety of other mutations the same gene that result in cystic fibrosis.”

So while there is no radical transformation of stem cell technology, its incremental improvements are constantly moving the science forward.