Researchers at New Jersey Institute of Technology (NJIT) say they have developed a way to quantify drug products and impurities faster, more accurately, and less expensively than traditional proteomic absolute quantitation strategies. This suggests a significant improvement in quality-control testing for monoclonal antibodies and other protein-based therapeutics.

The new method is based on electrochemical oxidation of surrogate peptides and analysis via coulometric mass spectrometry (CMS) to measure their oxidation yield. This eliminates the time and expense of synthesizing stable, isotype-labeled peptides or proteins as internal standards, leading to potential paradigm shift in biopharmaceuticals testing.

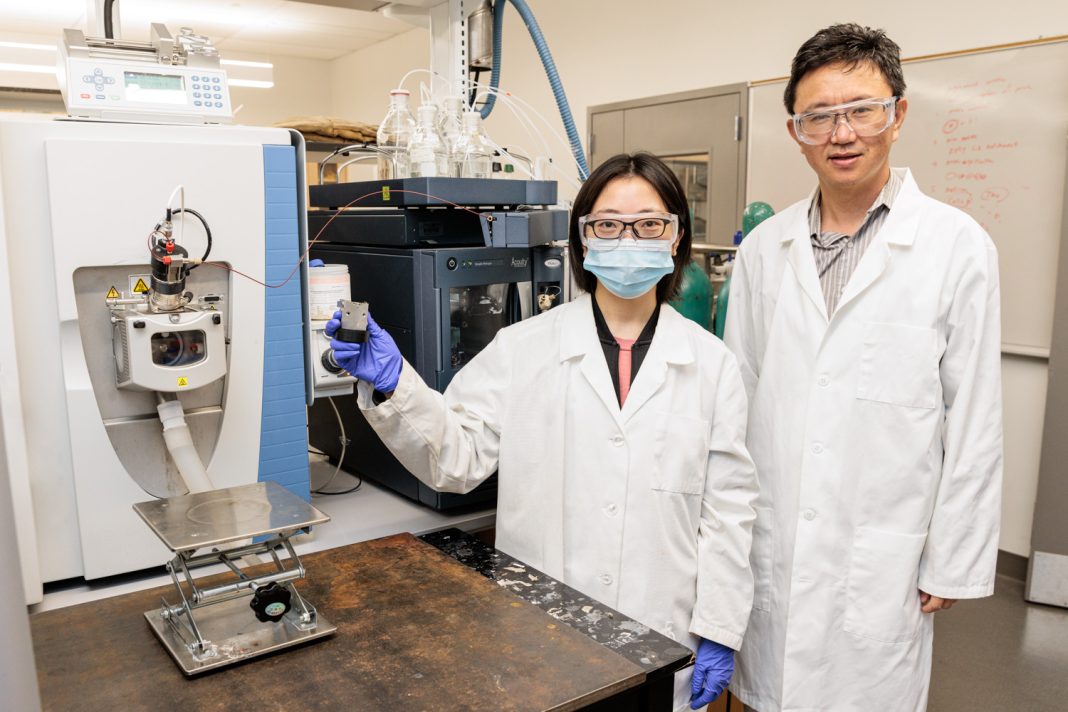

As Hao Chen, PhD, professor, New Jersey Institute of Technology and corresponding author of a recent paper, tells GEN, “Traditional methods use isotope-labeled standards for absolute quantitation, but the synthesis of isotope-labeled standards takes several weeks. Using our method, we don’t need to wait for the synthesis and shipping of isotope-labeled standards and can start quantitation right away.”

In practice, researchers separate the peptides after protein digestion and introduce surrogate peptides that produce an electrical current as they oxidize. This, when considered alongside the oxidation yield, enables absolute quantitation.

Absolute quantitation of β-lactoglobulin B

Chen’s PhD student and first author Yongling Ai, and the team used this method for absolute quantitation of β-lactoglobulin B, α-lactalbumin, and carbonic anhydrase in a mixture in a single run without requiring internal standards. Importantly, quantitation is accurate even for low-level target proteins in a mixture. “For instance,” the team wrote, “500 ppm of PLBL2, a problematic host cell protein, in the presence of a highly abundant monoclonal antibody was successfully quantified by CMS with no use of standards.”

The study also successfully quantified the formation of succinimide, a product of protein degradation, which the team says never before has been accomplished with absolute quantification because of the lack of standards. Chen says this ability may lead to deeper insights into the process of degradation for therapeutic proteins.

This new quantification method is important because of the growth in manufacturing protein-based therapeutics. The needs, Chen says, are two-fold. “One, protein-based drugs are grown in cells so once harvested, they may contain unwanted host-cell proteins. Two, protein-based drugs could undergo degradation or oxidation after manufacturing.” In both cases, monitoring and quantification are needed.”

Next, the Chen lab plans to use this method to quantify up to thousands of proteins per run and to enhance the sensitivity of the CMS for low protein levels. “We are starting to work with Merck & Co. to test implementation of our method for measurements of proteins in pharmaceutical settings,” Chen says.

The research was conducted with researchers from Merck, Johnson & Johnson, and Ohio University.