A benchtop tool for detecting empty-full viral capsids for gene therapy applications has added the capability to work in commercial-scale manufacturing. That’s according to James Wilkinson, PhD, VP of strategic business development at Refeyn, the company that developed the instrument. Wilkinson spoke about its new capabilities in a Dragon’s Den session at bioProcessUK in November.

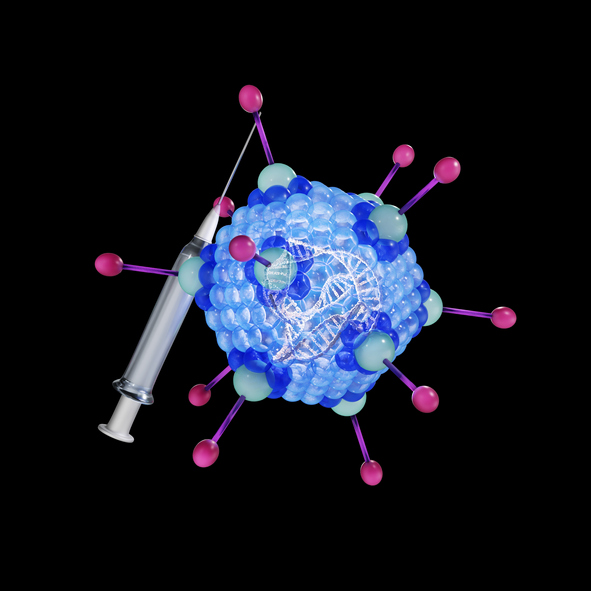

Refeyn’s mass photometer uses light scattering to solve a major problem in gene therapy manufacturing—whether the protein shell (capsid) of adeno-associated viruses (AAVs) used in gene therapy is full of the DNA that acts as the drug.

Refeyn, which is five years old and a spinoff from the U.K.’s University of Oxford, uses light scattering to measure the mass of the capsids to determine if they contain “drug” DNA.

According to Wilkinson, this approach differs from other light-scattering methods that use the size of particles as a “very good” proxy for mass. These can’t detect the difference between empty and full capsids, as they have the same radius, he says.

Novel technology

The mass photometer is a new technology, continues Wilkinson, and is smaller and cheaper than more established methods for measuring empty-full capsids. This, he says, should help smaller biotechs that can’t afford more expensive and complex instruments.

“[With these established methods], a single sample takes up to twenty-four hours to run and the level of expertise you need to run one of these potentially multi-million-pound machines is quite extensive,” he adds.

According to Wilkinson, smaller companies often turn to outsourcing partners and the process can take a week, i.e., to send out the sample, get the data analyzed, and get results returned.

In contrast, he says “our [instrument] is benchtop, can be used in a normal lab by technicians, and [costs] about $175,000. It allows people to get their data quicker, which then allows them to optimize their process development, as well now manufacturing these particles.”

At the Dragon’s Den, Wilkinson presented on the addition of Good Manufacturing Practice (GMP) compliance to the company’s mass photometry instrument, which has been on the market for about two years. This now allows it to be used throughout the manufacturing process.

The company has also recently added the ability to measure the titer of capsids. “Our technology counts individual particles so, if you know how many you have and how many are empty-full, you’ve got a decent picture of what’s in your [test] tube,” he says.

Refeyn has now launched a system to work on larger viruses, including adenoviruses and lentiviruses.