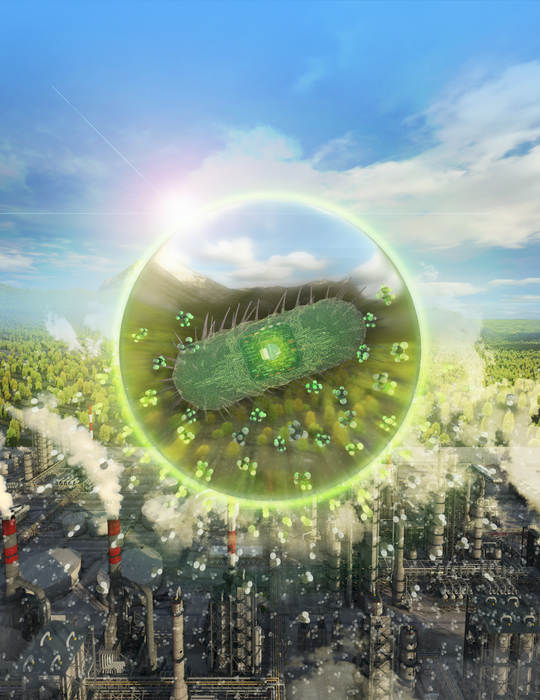

Bacteria are known for breaking down lactose to make yogurt and sugar to make beer. Researchers headed by teams at Northwestern University, LanzaTech, and Oak Ridge National Laboratory (ORNL) have now selected, engineered, and optimized a strain of Clostridium autoethanogenum bacteria that can convert waste carbon dioxide (CO2) selectively into industrial chemicals. The scientists developed an efficient new carbon-negative process that could convert the waste gases, such as emissions from heavy industry or syngas from any biomass source, into the industrial chemicals acetone or isopropanol (IPA).

The new gas fermentation process—which the team tested at industrial pilot scale—removes greenhouse gases from the atmosphere, and also avoids using fossil fuels, which are typically needed to generate acetone and IPA. After performing life-cycle analysis, the team found the carbon-negative platform could reduce greenhouse gas emissions by 160% as compared to conventional processes, if widely adopted.

“The accelerating climate crisis, combined with rapid population growth, pose some of the most urgent challenges to humankind, all linked to the unabated release and accumulation of CO2 across the entire biosphere,” said Northwestern’s Michael Jewett, PhD, co-senior author of the study. “By harnessing our capacity to partner with biology to make what is needed, where and when it is needed, on a sustainable and renewable basis, we can begin to take advantage of the available CO2 to transform the bioeconomy.”

Jewett is the Walter P. Murphy professor of chemical and biological engineering at Northwestern’s McCormick School of Engineering and director of the Center for Synthetic Biology. He co-led the study with Michael Koepke, PhD, and Ching Leang, PhD, both researchers at LanzaTech. Their development is reported in Nature Biotechnology, in a paper titled, “Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale.”

Most “commodity chemicals” are derived exclusively from fresh fossil resources, such as oil, natural gas, and coal, the authors explained. Acetone and isopropanol are two such chemicals, which have a combined global market value in excess of $10 billion. Both represent industrial bulk and platform chemicals, and are used as industrial solvents, and platform chemicals for the production of other materials. For example, acetone is used as a solvent for many plastics and synthetic fibers, thinning polyester resin, cleaning tools, and nail polish remover. IPA is a chemical used in antiseptics, disinfectants, and detergents, and can represent part of a pathway to commercial plastics such as polypropylene, which is used in both the medical and automotive sectors. Both acetone and IPA are used in acrylic glass. IPA is, in addition, a widely used disinfectant, serving as the basis for one of the two World Health Organization-recommended sanitizer formulations, which are highly effective against SARS-CoV-2. “Additionally, acetone has potential in the fuel sector to reduce emissions and enhance the performance of existing fuels and as a precursor for green diesel or jet fuel substitutes,” the authors continued.

While IPA and acetone are thus incredibly useful, they are generated from fossil resources. “Manufacture of both acetone and IPA is dependent on propene cracking or reforming, which are energy-intensive processes that create hazardous waste and greenhouse gas (GHG) emissions,” the investigators added. “No viable green chemistry alternatives are available.”

Microbial fermentation—used in the food industry to make yogurt, beer, and other products—is a promising approach for manufacturing a wide variety of chemicals from non-fossil fuel sources. Most work in this field has relied on microbes that ferment sugars; however, the use of sugars as a raw material is costly and raises the total greenhouse gas emissions of the production process. Certain bacteria, however, are capable of gas fermentation—converting gases such as CO2 into more complex molecules. This has opened up the opportunity for gases found in industrial emissions or generated from biomass and municipal waste to be turned into useful products.

The collaborators now report on the development of a gas fermentation process for carbon-negative production of either acetone or IPA. The team reprogrammed LanzaTech’s commercial ethanol-producing C. auto bacterial strain through cutting-edge synthetic biology tools, including combinatorial DNA libraries and cell-free prototyping advanced-modeling, and omics. The scientists relied on a three-pronged approach that harnessed innovations in pathway refractoring, strain optimization, and process development to achieve the observed level of performance. “Specifically, we integrated high-throughput strain engineering workflows, omics analysis, cell-free systems, kinetic modeling, fermentation scale-up, and life-cycle analysis (LCA),” the authors explained. “Using a combinatorial pathway library approach, we first mined a historical industrial strain collection for superior enzymes that we used to engineer the autotrophic acetogen Clostridium autoethanogenum. Next, we used omics analysis, kinetic modeling, and cell-free prototyping to optimize flux.” Jewett added, “These innovations, led by cell-free strategies that guided both strain engineering and optimization of pathway enzymes, accelerated time to production by more than a year.”

The optimized process was scaled up to the pilot plant, with life-cycle analysis demonstrating significant GHG savings. “ … we scaled-up our optimized strains for continuous production at rates of up to ~3 g/L/h and ~90% selectivity,” the team stated. “LCA confirmed that acetone and IPA produced by gas fermentation have a negative carbon footprint of −1.78 kgCO2e/kg of produced acetone and −1.17 kgCO2e/kg of produced IPA.”

“Conversion pathways for the production of any biofuel or bioproduct, including acetone and IPA, inevitably involve chemical byproducts that can cause or be the result of major bottlenecks,” said ORNL’s Tim Tschaplinski, PhD. “We used advanced proteomics and metabolomics to identify and overcome these bottlenecks for a highly efficient pathway. This approach can be applied to create streamlined processes for other chemicals of interest.”

By proving scalable and economically viable bulk chemical production, the researchers have set the stage for implementation of a circular economic model in which the carbon from agriculture, industrial, and societal waste streams might be recycled into a chemical synthesis value chain to displace ever-increasing volumes of products made from virgin fossil resources. Chemical synthesis could then become offer a path to capturing, recycling, and utilizing waste carbon resources. “These innovations, led by cell-free strategies that guided both strain engineering and optimization of pathway enzymes, accelerated time to production by more than a year,” Jewett said.

The Northwestern and LanzaTech teams believe the developed strains and fermentation process will translate to industrial scale. The approach also could potentially be applied to create streamlined processes for generating other valuable chemicals. “This discovery is a major step forward in avoiding a climate catastrophe,” said Jennifer Holmgren, LanzaTech CEO. “Today, most of our commodity chemicals are derived exclusively from new fossil resources such as oil, natural gas, or coal … The acetone and IPA pathways developed will accelerate the development of other new products by closing the carbon cycle for their use in multiple industries.”

The team further concluded in their paper, “Unlike traditional production processes, which result in release of greenhouse gases, our process fixes carbon. These results show that engineered acetogens enable sustainable, high-efficiency, high-selectivity chemicals production. We expect that our approach can be readily adapted to a wide range of commodity chemicals.”

In an accompanying News and Views, Corinne D. Scown, PhD, and Jay D. Keasling, PhD, at the Biological Systems & Engineering Division, Lawrence Berkeley National Laboratory, noted that the reported study described by Jewett and colleagues “… provides a roadmap for broadening the range of molecules that can be manufactured sustainably from waste and biomass feedstocks.” They suggest that the progress reported offers “hope that acetogens and other non-model organisms will have a meaningful role in a more sustainable future.” And as they concluded, “Creating a circular or even net-negative industrial sector through novel synthetic biology approaches will not solve the climate crisis on its own, but it can tackle some of the most difficult-to-decarbonize parts of the global economy.”

Comments are closed.