A new biomanufacturing method for constructing 3D scaffolds composed of narrow fibers with specific alignments has been developed. The method, called focused rotary jet spinning (FRJS), is enabling researchers to fabricate heart structures and to study how the helical alignments of fibers in the musculature of the heart enhance cardiac function.

The findings, which provide proof-of-concept for a streamlined approach to engineering tissues and organs with complex 3D geometries, were reported by Huibin Chang, PhD, a research associate in bioengineering at Harvard University, and colleagues in a Science article entitled “Recreating the heart’s helical structure-function relationship with focused rotary jet spinning.”

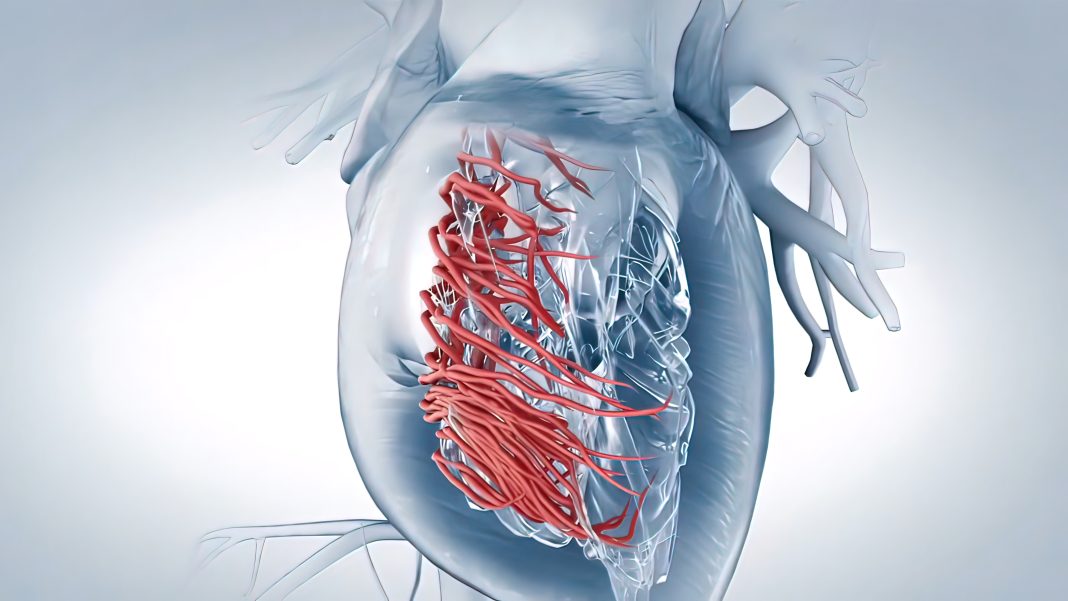

The heart’s pumping action comes from cardiomyocytes—the muscle cells of the heart—which are organized as helical fibers that envelop the ventricles. With each beat, this arrangement results in a combined contracting and twisting motion.

“However, it is difficult to specifically assess the extent to which the heart’s helical structure contributes to its function,” wrote Michael Sefton, ScD, and Craig Simmons, PhD, from the Institute of Biomedical Engineering at the University of Toronto, in a perspective that accompanied the research article. “To that end, understanding and replicating the heart’s helical structure-function relationship is thought to be an important step.”

Designing scaffolds and materials that adequately recapitulate native heart function can be challenging. The newly reported FRJS method offers improvements in fabrication speed and complexity over conventional methods.

In FRJS, long, free-floating polymer fibers are expelled by centrifugal force, and air jet streams align and deposit the fibers on molds. By controlling the shape and rotation of the mold, scaffolds with specific fiber orientations can be constructed. The scaffolds can then be seeded with cells—cardiomyocytes, in this case—to recapitulate tissue and organ structures.

Using their method, Chang and colleagues fabricated heart ventricles with similar structural properties to those in natural human hearts. They also fabricated models of diseased hearts with misaligned fiber orientations. Once the scaffolds were seeded with human cardiomyocytes, the authors showed that the helical architecture increased cardiac performance, illustrating that the helical tissue pattern plays a role in the pumping function of the heart.

But the heart is more than a pump. To achieve a fully functional bioengineered heart for use in regenerative medicine, an electrical conduction system, vasculature, and means to avoid immune responses are still needed.

The FRJS method provides an initial pathway toward fabricating more complex tissues and organs. “In addition to biofabrication, FRJS may serve an important role in other additive manufacturing processes,” wrote Chang and colleagues. “It provides production rates comparable to those of current industrial processes while enabling micro/nanoscale feature sizes and controlled 3D alignments.”