The ultimate 3D display technology, the Star Trek holodeck, was usually wasted on recreation. To think that it could have been used to create monumentally large cellular structures and even individual molecules! One day, real holodecks will be available, and scientists will put them to good use. In the meantime, scientists can still accomplish a lot if they use 3D nanoscale intra- and intercellular imaging technology. It is already available from Double Helix Optics.

“We give scientists full X, Y, and Z information about cellular structures, says Leslie Kimerling, co-founder and CEO, Double Helix Optics. “We provide visualization tools that let scientists look at cells in 3D without interpolation.”

This company has expertise in super-resolution photon-efficient imaging by nanometric double-helix point spread function localization of emitters, or SPINDLE. In fact, the company has developed a microscope upgrade technology called SPINDLE®. It is a module that attaches to virtually any widefield microscope to enable particle visualization and precision tracking down to the single-molecule level in 3D. Consequently, it collects information that otherwise can’t be recovered by 2D technology.

“If you’re looking at cellular activity, nothing moves in a straight line,” Kimerling elaborates. “In 2D, you are not able to follow that movement. You have to assume its path of travel. With SPINDLE, you can track its actual movement across time and planes.”

Double Helix Optics asserts that SPINDLE fits onto existing microscopes, cameras, or other optical instruments, including Olympus, Zeiss, Leica, and Nikon, and that integration is seamless. By selecting from a library of engineered phase masks (double helix, long range, extended depth of field, and multicolor), researchers can match SPINDLE to specific depths, emission wavelengths, and system setups. Then, researchers can use the company’s 3DTRAX™ software to accomplish reconstruction and data analysis. According to Kimerling, SPINDLE is the only instrument offering this combination of depth and precision for super-resolution single-molecule study.

Achieving greater depth

“In the 1990s and early 2000s, super-resolution techniques became possible that allowed visualization below the diffraction limit of light,” Kimerling relates. “A group of technologies allowed XY precision below 200 nm, breaking what had been a 150-year-old

limit.” This breakthrough finally made it possible to see nanostructures, but only in two dimensions.

In the early 2000s, the 2D limitation was surmounted. Double Helix Optics’ co-founder and chief innovation officer, Rafael Piestun, PhD, worked with 2014 Nobel laureate William Moerner, PhD, a professor of chemistry at Stanford University. Together, the scientists made it possible to see nanostructures in 3D.

Moerner’s work, known as super-resolved fluorescence microscopy, turned the fluorescence of individual molecules on and off while multiple images are taken of the area occupied by the molecules. When the images are superimposed onto each other, they create a dense image with nanoscale resolution.

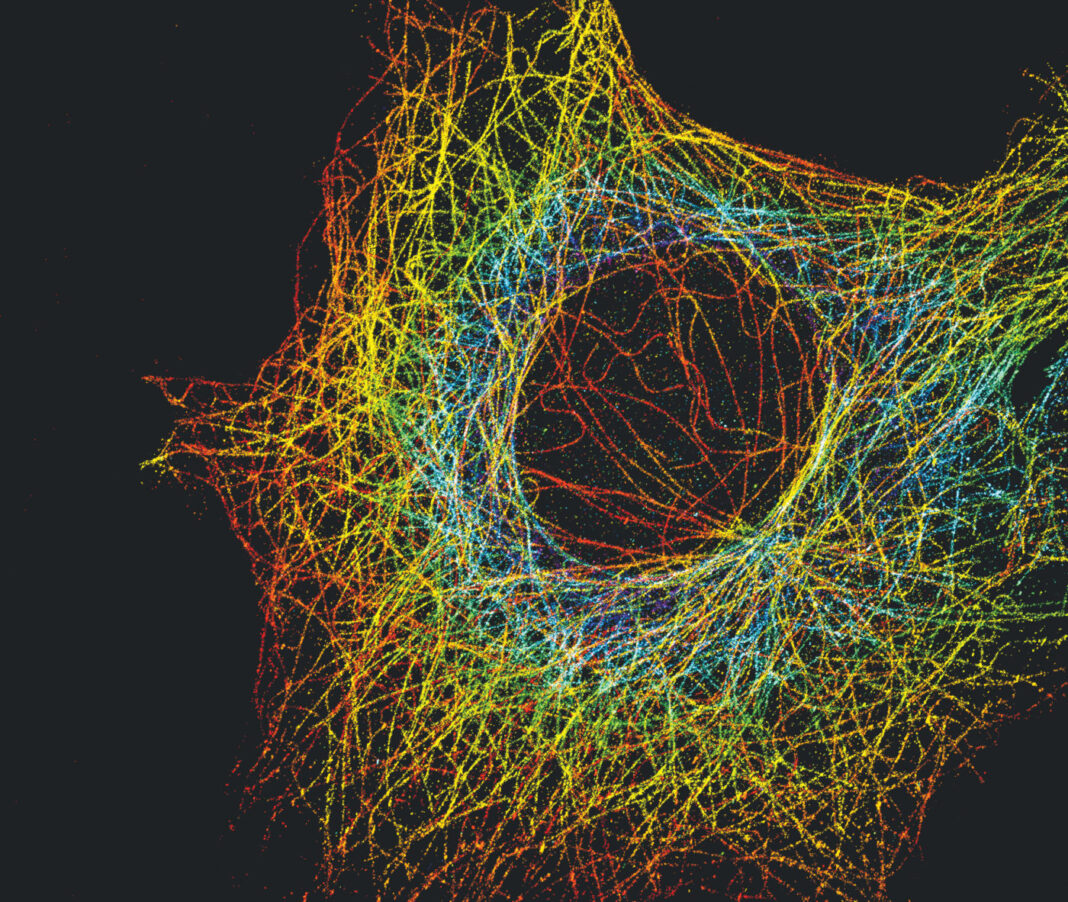

According to Kimerling, Double Helix Optics has developed technology “to extend single-molecule localization microscopy to enable 3D nanoscale imaging with precision levels of 10 to 20 nm in X and Y and of 20 to 25 nm in Z, with extended depth of multiple microns in a single image.” This technology, which Double Helix Optics calls Light Engineering™ technology, utilizes phase masks, specially designed optical elements that effectively “change the response system of a 2D optical system—a microscope, for instance—and convert its 2D shots into 3D information captures,” says Kimerling. Using the data generated by the phase masks, the company’s 3DTRAX software automatically calculates the position of particles in three dimensions.

“This is single-shot imaging, not scanning,” Kimerling emphasizes. The distinction is important because single-shot images offer up to 6 times and sometimes as much as 20 times more depth information than a single scan, depending on the phase masks that are used.

Transitioning from concept to reality

Kimerling and Piestun founded Double Helix Optics in 2013 to enable researchers to make new discoveries, Kimerling says. Funding from a National Science Foundation grant helped to take the company’s technology from concept to reality. As proof of concept was achieved, Small Business Innovation Research (SBIR) grants supported further development.

Initially, as with any innovation, researchers were skeptical. “The early adopters were researchers who were looking for an edge,” she recalls. “When others saw interesting research coming from this and realized they didn’t have to replace their microscopes to go from 2D to 3D, they were intrigued. They wanted to know more.”

Today, SPINDLE is used for applications in medical research (such as the study of cancer, dementia, and other diseases), biopharmaceutical development, plant biology, and even industrial inspection. Most of the applications in the life sciences involve the study of disease mechanisms or the development of cell-based assays—or both. (Researchers that improve their understanding of how disease can alter cellular morphology may find new ways to attack disease.) Currently, SPINDLE is helping researchers see 3D images of stress granule cores in neurodegenerative diseases, and to reconstruct complete T cells in immunology.

Eyeing machine vision

In 2019, the International Society for Optics and Photonics (SPIE) named SPINDLE the winner of the Prism Award in diagnostics and therapeutics. “That’s the ‘Oscar’ of optics,” Kimerling says. At the same time, Double Helix Optics also won $1 million in funding from the Luminate accelerator program for optics and photonics. One year later, in 2020, the company announced product enhancements that include an expanded phase mask library for whole cells and single molecules, and applications for machine inspection and machine vision.

Double Helix Optics is still a small company, and it faces the challenges that beset most small companies. For one, its location in Boulder, CO, is far from the U.S. optics epicenter of Rochester, NY. Synergy isn’t lacking, however. The Luminate accelerator is helping Kimerling form strong ties with the larger optics community, as well as possible collaborators and investors.

Going forward, the company will continue developing its phase mask library for 3D imaging and extended depth of field recovery. “Different applications have different requirements,” says Kimerling. “So, we’re focusing on features that reflect our customers’ priorities.” Examples are masks for high-content screening that reveal whole cells in 3D, and masks that extend our understanding of how assays impact their targets. The company also is developing additional strategies to help researchers accomplish more, faster.

The future of science will be in 3D. “That’s where we’re going,” Kimerling declares. “Innovations in machine vision will make it possible to capture even more data, providing full sets of information about cells or objects that further strengthen learning.” Soon, researchers may begin exploring 3D microscopy in the virtual world.

Double Helix Optics

Location: 3415 Colorado Avenue, Boulder, CO, 80303

Phone: (303) 492-0707

Website: www.doublehelixoptics.com

Principal: Leslie Kimerling, Co-Founder and CEO

Number of Employees: 10

Focus: Double Helix Optics extends Nobel Prize–winning technology that lets researchers see 3D nanostructures using traditional widefield microscopes and a special add-on module. It also enables 3D particle tracking with precision depth.