July 1, 2018 (Vol. 38, No. 13)

Evolving Technologies Help Make It Easier to Meet Regulatory Requirements

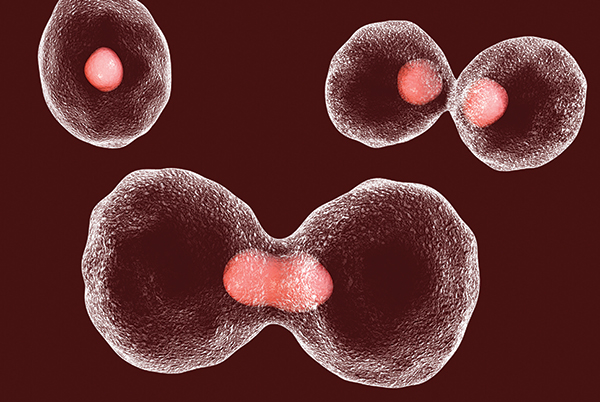

Regulatory agencies say that recombinant proteins intended for therapeutic use must be produced from a cell line derived from a single progenitor cell. In addition, single-cell cloning has gained increasing importance as genome editing techniques have entered routine laboratory practice.

Pure clonal isolation from a single progenitor cell is a critical step in the genetic and functional characterization of mutations achieved by targeted genome editing methods such as those incorporating ZFNs, TALENs, and CRISPR-Cas9. These nuclease-driven genome editing tools can be used to introduce a change at a specific genomic location, either to cause a mutation or to insert an exogenous sequence.

However, culturing edited cells results in a heterogeneous polyclonal cell population requiring generation of an edited cell line containing a homogeneous genetic background to retain the desired genotype and to facilitate downstream phenotypic characterization.

While traditionally the most laborious and time-consuming step in CRISPR-based genome engineering using cell models, the generation of clonal mutant cell lines, investigators say, is absolutely required to draw any solid conclusions correlating a given mutation and cellular behavior.

In the development of biopharmaceutical production cell lines, current workflows have drawbacks that include reduced cell viability, inefficient single-cell isolation, and limited evidence for clonality.

Chinese hamster ovary (CHO) cells remain the major cells of choice for the manufacture of therapeutic recombinant proteins. However, one of the major challenges in CHO cell line generation remains efficient identification of high-producing clones among a large population of low-producing or non-productive clones. It is not unusual for several hundred individual clones to be screened for the identification of a commercial clonal cell line with acceptable productivity and a growth profile appropriate for large-scale production.

Cloned colonies of Bon cells, a human carcinoid tumor cell model. An agarose overlay method was used to pick isolated colonies. The method was developed in the laboratory of Iris Lindberg, Ph.D. With this method, clonal cell lines from HEK, CHO, AtT-20, RIN, euro2A, and several other common and neuroendocrine cell lines have been derived. The black circles are early-appearing colonies, and the blue circles are later-appearing colonies. [Iris Lindberg, Ph.D., Professor of Neurobiology and Anatomy, University of Maryland Medical School]

Isolation Techniques

Limiting dilution, the traditional method for isolating single cells, relies on statistical probabilities for monoclonality that can vary significantly with slight changes to protocols. The technique, while highly inefficient at isolating single cells, preserves cell viability. Conversely, flow cytometry can provide strong evidence of monoclonality and high efficiency but negatively affects cell viability.

Proponents of cloning in semisolid medium, in which cells are suspended in viscous medium, say it leads to the formation of easily isolated colonies and that it can be used to isolate monoclonal cell lines in less time and using fewer resources compared with limiting dilution selection and cloning. Solutions range from media tweeks to the use of systems that “print” single cells and produce sequential images to show that a cell colony did indeed arise from a single cell.

For example, Molecular Devices’ CloneSelect™ Single-Cell Printer™ (SCP) utilizes microfluidics technology and real-time image analysis to sort and deposit single cells into standard microplates. The system can print a 96-well plate in 5 to 10 minutes and works with 384-well plates. Five images capture single cells as they are dispensed, providing image-based evidence of monoclonality that can be used in regulatory filings.

Cell imaging systems have been evolving to meet imaging demands, enabling better imaging that permits identification of single-cell clones, the ability to see a single cell on the day of seeding, and better visibility along well edges.

“Single-cell cloning is, in part, a response to FDA guidance,” says Tim Smith, technical product manager at Nexcelom. Nexcelom designs, manufactures, and markets its Cellometer and Celigo image-cytometry products for cell analysis in life sciences and biomedical research.

Smith notes that guidance documents from the FDA and the International Conference on Harmonization of Technical Requirements for Registration of Pharmaceuticals for Human Use state that the cloning procedure should be fully documented, with details of imaging techniques and/or appropriate statistics.

For proteins derived from transfection with recombinant plasmid DNA technology, a single fully documented round of cloning is sufficient, provided that product homogeneity and consistent characteristics are “demonstrated throughout the production process and within a defined cell age beyond the production process,” noted Genentech scientists (Shaw et al.) in Biotechnology Progress.

Nexcelom’s Celigo imaging system provides an image from day zero, showing only a single cell in the well and creating documented proof of single-cell clonality. “Single-cell cloning is becoming much more popular due to regulations and people have seen benefits,” Smith asserts. “With the technology available now, it’s a lot easier. You have an image in two minutes before you have to go through genetic characterization, allowing much higher throughput.

“The unique thing about our instrument is the way the optics are set up. We can image an entire 96-well plate very fast without having to move the plate, capturing 16 images of a single well in milliseconds, and we can do 96 wells in two minutes.”

Iris Lindberg, Ph.D., professor of neurobiology and anatomy at the University of Maryland Medical School, tells GEN that her lab’s method of picking desired clones arose from the need to speed up cloning of individual colonies derived from cell lines that are difficult to efficiently transfect, notably endocrine cells.

Dr. Lindberg is particularly interested in neuropeptide and peptide hormone maturation in neural and endocrine cells; she first used the technique to isolate proenkephalin-overexpressing AtT-20 cell clones (after antibiotic selection). Rather than use cloning rings—which Dr. Lindberg referred to as so “1950s”—she and her team developed an agarose overlay method to pick isolated colonies.

“We reasoned that we should be able to keep cells moist and hopefully aerated with a thin layer of molecular biology–grade agarose containing physiological concentrations of salts and glucose. We circled well-separated colonies with a marker, removed the medium, added warm melted agarose/DMEM, waited a minute for the agarose to solidify, and then rapidly punched out isolated colonies of about 50 to 100 cells with sterile truncated pipette tips. Indeed, an experienced operator can pick 48 clones from a 10-cm dish in 15 to 20 minutes—a far more rapid pace than using cloning rings,” explains Dr. Lindberg.

“Remember to supplement the isolated colonies with fetal bovine serum if your cells are finicky,” she cautions. “For some cell types, 50 cells alone will often die without added serum.” She notes that the major problem others had with the technique is “in not correctly gauging the temperature of the sterile agarose, which must fall within a narrow range—warm and pourable, but not “hot hot.”

The Verified In-situ Plate Seeding (VIPS™) single-cell cloning system from Solentim is a unique “all-in-one” system which combines gentle seeding of single cells with immediate image confirmation of the single cell in the destination well. The VIPS system can generate a resultant output 96-well plate with high seeding efficiency rapidly; and due to the low-pressure, gentle nature of the dispensing method, the majority of these wells will go on to form colonies resulting in high cloning efficiencies.

VIPS has to be initially purchased by customers for suspension CHO cells, but due to the gentle nature of the method, it should be well suited to a variety of other cell types which are normally damaged by FACS. VIPS is also incredibly easy to use and maintain, as compared to a FACS system.

VIPS dispenses single cells directly onto the bottom of a dry well in a microtiter plate, confirms immediately the presence of a single cell, fills the wells with media, and then images the whole well—thereby eliminating the need for a separate whole-well imager.

“Through the repeated droplet dispensing and imaging step, a record of single-cell deposition is created, and this iterative process is repeated several times over per well to ensure that a final plate with a high occupancy of single wells is achieved. “This gives you documentation for regulatory assurance that colonies growing in wells resulted from a single starting cell,” says Ian Taylor, Ph.D., sales and marketing director, Solentim.

“For biotherapeutics, the FDA requires assurance of clonality in the form of documentation. VIPS offers options for fluorescence validation and Clonality Report software, which is a documentation package for the clones of interest,” Dr. Taylor notes.

This Clonality Report includes all the specific requirements from the FDA guidance including whole-well image, location of the single-cell feature, zoom-in of the single-cell feature for day zero, and subsequent daily imaging along with full audit trail of those clones.

“Once wells and time points have been selected, a report is automatically generated as a PDF or PowerPoint. This report can be included as part of an IND submission, given to the cell banking or manufacturing group, or provided to a CMDO client as part of the cell line project deliverables,” Dr. Taylor explains.

The VIPS single-cell cloning system from Solentim is a small-footprint system that can sit inside a standard biosafety cabinet.

Downstream Considerations

For applications that require single-cell cloning, challenges include survival of individual clones and verification of monoclonality. Also, single-cell cloning has historically required the use of serum, which is undesirable for many downstream applications.

“We invest a great deal in optimizing our culture media to support cells during single-cell cloning, a key yet stressful stage of cell line development,” says Grace Tharmarajah, Ph.D., product marketing manager for research and development at Stemcell Technologies. “We produce media that promote the single-cell survival and increased cloning efficiency of human ES and iPS cells (CloneR™), as well as hybridomas, CHO, HEK-293, and other mammalian cell lines (ClonaCell™). CloneR™ is a serum-free supplement, and ClonaCell™ media formulations include serum-containing, serum-free, animal component–free, and animal origin–free options,” Dr. Tharmarajah adds.

Stemcell also offers specialized cultureware (AggreWell™) that can be used to compartmentalize and image the cells during clonal development to verify clonality of the resulting colonies. It is critical that the quality of the cloned cells, with respect to karyotype, for example, is not altered during the cloning process.

Single-cell cloning remains challenging for its practitioners, but individual process adaptations and evolving technology continues to make it more accessible.