Doppler ultrasound has the potential to noninvasively monitor cell culture concentrations and viability in real time, according to an industry research team led by Sartorius Stedim North America.

The method uses an ultrasound transducer mounted to the outer wall of a bioreactor to emit a 15 MHz ultrasonic burst through the reactor wall. Backscatter from the cells is collected by the same transducer and analyzed using multivariate data analysis (MVDA). This method accurately characterized and identified Chinese hamster ovary (CHO) cell concentrations between 0.01 x 106 cells/mL and 100 x 106 cells/mL, and cell viability between 3–99%.

This concept reduces the contamination risks associated with direct sampling and provides opportunities for perfusion applications and other control methods.

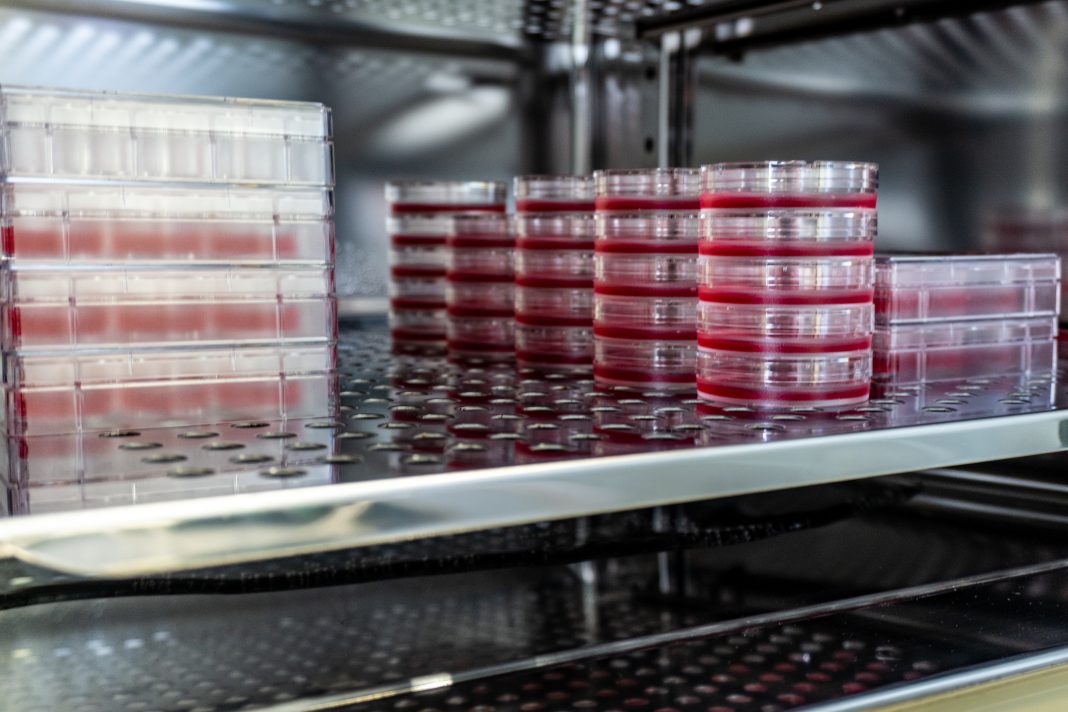

“Typically, cell concentration and cell viability are performed by optical methods (mostly microscopy-based techniques after the addition to trypan blue dye to mark dead cells) involving frequent sampling, which can be impractical, especially for small scale bioreactors,” first author Samin Akbari, PhD, a corporate research principal scientist at Sartorius, tells GEN. That’s because reducing the cell culture volume over time significantly changes the cell culture conditions, and frequent sampling increases the risk of contamination.

Standard optical measurements

The team also noted that the standard optical measurements used today can be inaccurate in concentrations above 10 x 106 cells/mL. Likewise, invasive readings for fed-batch cultures such as with Ramen spectroscopy and capacitance have some limitations linked to needs of detailed modeling and potential to be impacted by biofouling during long duration runs.

This Doppler ultrasound method eliminates those risks, but it is still in the research stage, Akbari cautions. For it to be accurate, “The cell culture process parameters such as stir rate and volume should be well-defined,” she says. Variations in such process parameters affect the ultrasound spectrum and, thus, results.

To increase this method’s possible value as a process analytical technique (PAT), the team is creating prediction models for a variety of cell culture process conditions, based upon MVDA techniques and Sartorius SIMCA software.

Next, she says, “We are expanding our experimental results to investigate the effect of different process parameters, including stir rate, volume, cell type, etc., on the ultrasound spectrum to create a more sophisticated prediction model… that will be accurate and robust [enough to allow biomanufacturers] to change process parameters. In parallel, we are developing miniaturized hardware to modulate the ultrasound sensor and acquire data,” Akbari adds.

If those experiments succeed, commercialization may follow.