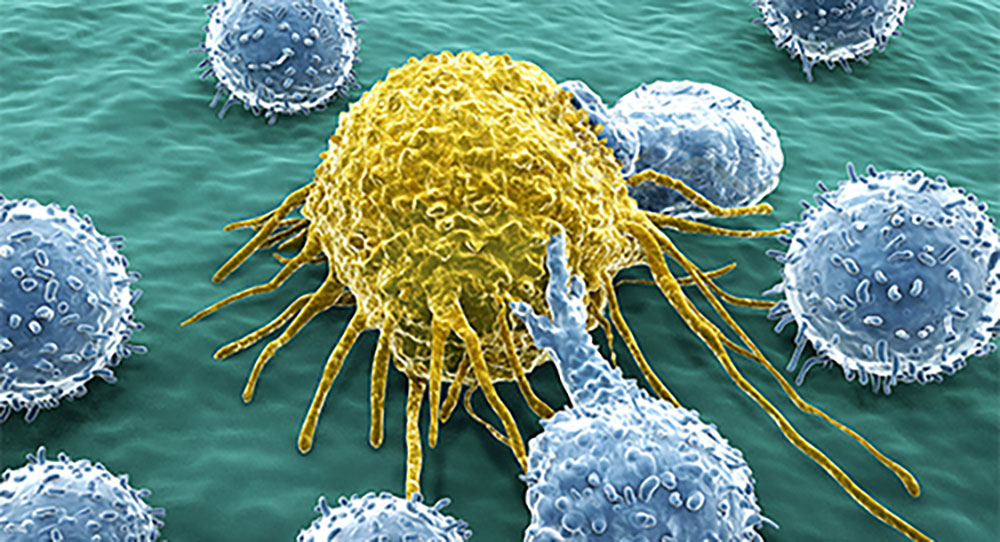

It’s never been easy to develop cancer treatments, but Artiva Biotherapeutics hopes to change that for natural killer (NK)-based therapies. “The patient experience of trying to get access to potentially life-saving cell therapy is fraught with challenges, high costs, and having to go to the hospital for treatments,” says company president and CEO Tom Farrell. “We can address all of that with off-the-shelf therapy.”

To do that, scientists at Artiva make allogenic NK-cell therapies. “We start with umbilical-cord blood that is selected for specific characteristics, including the affinity for the final NK cells to bind to an antibody and other aspects,” explains Artiva COO Peter Flynn. The blood from US-based cord-blood centers goes to a GMP facility in South Korea owned by corporate collaborators Green Cross (GC) for biomanufacturing that starts with a two-step process: first, depleting T cells; and second, expanding the NK cells on feeder cells in a proprietary process to create a master cell bank from each donor.

After characterization and quality control on 80–100 vials from a master cell bank, one vial is selected to seed a bioreactor process that generates the pure NK cell-based product. “Each run generates about 100 vials at 1 billion NK cells per vial,” Flynn says. “That’s a scale that we had not seen before—blood from a single donor patient potentially treating hundreds to thousands of patients,” adding that previous methods could only “treat a handful of patients from a single process.”

Next, the product must get to the patients. To do that, Artiva uses cryopreservation to make a frozen and infusion-ready product that can be shipped to clinical sites. So far, data suggest a shelf life of at least two years.

With all of those advantages, Artiva aims at another—cost. “We have a goal of production costs in the same ballpark as antibody-based therapeutics,” Flynn says. “We might not get quite that cost-effective, but we should be an order of magnitude lower than the cost of current allogenic processes.”

Later this year, Artiva plans to start a clinical trial with its AB-101, which is an NK-cell therapy for universal use in combination with monoclonal antibody therapy. The first trial will use an NK cell-based monotherapy, but it will also be tested later as a combination therapy with an anti-CD20 antibody in the treatment of relapsed refractory B-cell lymphoma. That will be just the beginning of the ways that Artiva plans to make therapies based on NK cells for blood-based and solid-tumor cancers combining Chimeric Antigen Receptor (CAR) technology with the NK manufacturing platform.

As Farrell says, “We want to open up cell therapy to all patients who need it.”