July 1, 2007 (Vol. 27, No. 13)

Annemarie Braun

George Oulundsen

Mobius MIX200 Works for Mixing Buffer, Media, and Protein Solutions

Biopharmaceutical companies are increasingly making the switch from stainless steel systems to disposable technologies. The reasons for this change are clear: lower risk of contamination, reduced cleaning and validation requirements, and increased flexibility in multiproduct facilities and biotech start-ups.

The Mobius™ MIX200 disposable mixing system is designed for mixing ingredients from intermediates to final drug products and for the preparation of process solutions such as buffers and media. The MIX200 system has a 200-L format and will later this year have 100-L and 500-L systems. The disposable mixer includes a process container with an integrated magnetically driven impeller, motor, and carrier.

Figure 1

Experimental Design

Three different solutions were tested in the disposable mixer. One-liter sample volumes were mixed on a stir plate to establish general baseline pH, conductivity, and absorbance measurements.

The disposable mixing system was bottom-filled with 200 L of RO-quality water and was set to 400 rpm. The powdered component was introduced into the system via a bung port at the top of the bioprocess container. Samples were taken from the process containers via a pipette from the top and a sample port on the bottom outlet of the container. The hold-up volume of the bottom sample port was drained prior to each measurement to eliminate false measurements from a dead-leg in the tubing.

The measurements were taken for at least 20 minutes and continued until at least 10 consecutive, stable, and matching measurements were recorded from the top and bottom. Visual inspection also confirmed that all of the powder went into solution.

Figure 2

Results

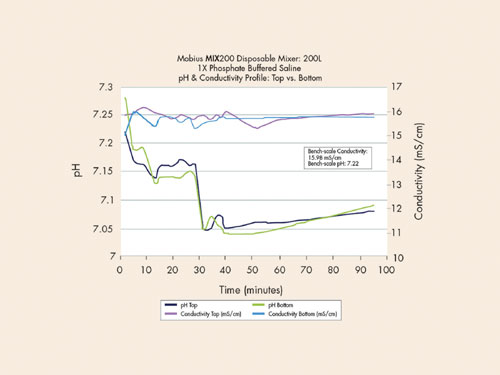

The results of the pH, conductivity, and absorbance from the three mixing trials are shown in the Figures:

Figures 1 and 2 plot the pH and conductivity values for the top and bottom measurements for 1X phosphate buffered saline and 1X Hank’s media.

Figure 3 plots the absorbance values and calculated concentration (calculated using Beer’s Law) of the bovine serum albumin samples taken from the top and bottom of the bag.

Figure 3

Discussion

The data for all three solutions showed that the Mobius mixer was able to homogeneously mix powder-liquid solutions at the tested concentrations in under 20 minutes. The data for the 10 mM PBS showed a decline in pH values after 30 minutes, but this was most likely due to chemical changes in the solution (e.g., dissolution of atmospheric carbon dioxide) that can be attributed to the weak buffering capacity of the solution.

The drop in pH was not a mixing phenomenon, and the mixture remained completely mixed even during the pH change within the solution. The figures clearly show that a homogeneous solution is achieved in 20 minutes or less for all three tested solutions.

Visual inspection of the process containers during mixing and draining of the system confirmed that, for the tested concentrations, the powders did not settle on the bottom or attach to the sides of the process container.

Due to the variation in solid-liquid mixing applications, it is recommended that each specific liquid-powder application be evaluated individually prior to implementation. However, the information presented in this document can be used as a reference for various buffer, media, and protein solutions.

Annemarie Braun and George Oulundsen are bioprocess engineers

at Millipore. Web: www.millipore.com. Phone: (781) 533-4152. E-mail: [email protected].