January 1, 1970 (Vol. , No. )

Bobby Chavli Hamilton Company

Annette Summers GeneCom Group

Find out how to make the right decisions for your lab.

PCR is a cornerstone technology for genetic research and many molecular diagnostic-based tests. As projects become larger and more clinics adopt PCR-based tests, consistency, speed and performance become increasingly important. Once a lab is routinely processing more than two 96-well plates, they usually begin to consider automating PCR.

Here are five expert tips for making the right decision for your lab.

1. Clarify your objective: Determine exactly what you intend to accomplish by adopting automation in your lab. Important factors to consider: what sections of your workflow you are interested in automating, what level of operator intervention you require, and the timeline for your project, among others.

2. Designing the optimal workflow takes a village: Finding instrumentation that has GUI-enabled programming and preprogrammed scripts is just the beginning. Automated workflows are slightly different from manual workflows. One example is how liquid handlers simplify the PCR cleanup process; the automated workflow has fewer steps than the manual workflow. A good collaborator can help you navigate this process.

3. Nominate an in-house expert: Automating a manual PCR workflow may involve changing the sample plate map, which will subtly change the liquid handling workflow. When it comes to creating the automation program, an in-house expert collaborating with an automation instrument supplier will make the process much more successful.

4. Calibrate your system—the three C’s: Automated PCR, just like the manual version, depends on integrity between the chemistry and the process. Here is a mnemonic to ensure your system runs optimally:

- Use a Calibration curve, or standard curve, to determine the relative or absolute values of your PCR product.

- Conduct a Cross-contamination evaluation by using a simple checkerboard test. The checkerboard results from PCR products run on an agarose gel. The PCR product should produce the same result in bands corresponding to a positive control well and then alternating with a blank well from a negative control.

- Confirm temperature constancy within the thermal cycler block. Each thermocycler regulates its temperature precisely, but sample volume can vary. The thermal-insulating properties from sample volume may affect the temperature transfer from the block to your sample. This is especially important for low- and high-volume samples. Determine if you need to alter cycle times to get the same yields.

5. Maximize your automation investment dollar—choose a future-proof system: It’s critical to find a system that is as close to future proof as you can get. Look for these three key attributes: hardware compatibility, application flexibility, and an open reagent platform. If your throughput changes, you may need to expand automation to additional applications, so application and third party hardware compatibility becomes important. In addition, a platform that can work with any PCR reagent kit insulates your lab from single-source reagent problems, such as a kit discontinuation.

In the short run, investment in automation will enable higher productivity, less hands-on time and fewer wasted reagents. These cost savings will equal the instrument’s purchase price and installation cost within the first year. Your return on investment, however, is generated in the end and depends more heavily on which platform you choose.

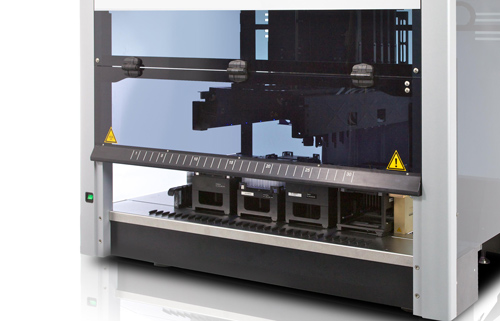

The Hamilton PCR Setup STARlet® workstation is an example of a device researchers can use for automated PCR sample prep.

Bobby Chavli works for Hamilton Robotics and Annette Summers works for GeneCom Group.